BY TANYARADZWA NHARI HUAYOU Cobalt, the Chinese conglomerate that recently took over Arcadia Lithium Project in Zimbabwe, has shut doors on prospects for establishment a final refinery, saying Harare lacked supporting infrastructure to run a viable operation.

TheChinese conglomerate listed outfit unveiled a plan to establish a processing plant — part of a US$300 million budget — that converts ore into matte, before shipment to China for further refinement.

The final product would then be fed into Cobalt’s electric vehicles battery production facility to produce batteries.

Establishment of final refineries has been topical since platinum miners established operations in Zimbabwe from 2000, shipping matte for final refinery in South Africa.

There has been fears that several by – products of the final refinery process, such as gold have not been fully accounted for.

In 2020, government imposed a 15% platinum beneficiation tax to force firms to establish refineries, but this was dropped about two weeks ago, before it came into force.

In a note to Standardbusiness, Cobalt said it did not directly export ore, but had invested huge amounts to build a high-tech concentrator for processing lithium.

“The large scale investment not only drives the development of the local economy and creates a large number of employment opportunities, but also contributes value to the improvement of local equipment level,” Cobalt said.

- Chamisa under fire over US$120K donation

- Mavhunga puts DeMbare into Chibuku quarterfinals

- Pension funds bet on Cabora Bassa oilfields

- Councils defy govt fire tender directive

Keep Reading

“The establishment of a converter for producing battery-grade lithium carbonate is not feasible for the following reasons;

“First, the principal reason the production of battery grade lithium carbonate is not feasible is based on the lack of supporting and auxiliary material for battery-grade lithium carbonate production.

“For each tonne of battery-grade lithium carbonate production, it needs 2 800 kilowatts of green (renewable) power 500-600 m3 of natural gas, 2,2 tonnes of concentrated sulphuric acid (98,5%), two tonnes of first-class sodium carbonate, 20kg of first class sodium hydroxide, four tonnes of heavy calcium powder and 1,6 tonnes of food-grade carbon dioxide,” the firm added.

“There is a chronic shortage of these supporting and auxiliary materials in Africa and the costs incurred by the importation would be huge and unaffordable.

“It is worthy to note that processing enterprises will be uncompetitive in a global market without cost competitive inputs i.e raw materials, gas and powder and first-class sodium carbonate.”

Cobalt said the second reason was in respect of the development and economic analysis on the extension of lithium value chain.

“It is well understood that the five-year plan of the national strategy formulated by the Zimbabwean government sets our macro objectives to enhance and advance the value chain,” the Chinese firm said.

“However, this is a gradual process, which requires the relevant enabling industrial environment, infrastructure, raw materials, and technical competence to be present in order to create the competitive position of the lithium value chain.

“Therefore, based on our comprehensive analysis, we believe there is certain possibility in practice to establish a converter to produce lithium sulphate from the lithium concentrate within 10 years from the date of commencement of commercial production of lithium concentrate under Arcadia Project, subject to the availability of sufficient green (renewable) power, natural gas, sulphuric acid and heavy calcium powder in Zimbabwe and subject to the economic feasibility of production of lithium sulphate under Arcadia Project.”

The Arcadia Mine life span is estimated at 10 to 15 years, which means chances of a refinery might be narrow for now, unless fresh large reserves are discovered.

Last week Cobalt said it will pour US$300 million into Arcadia Lithium Mine and construct the processing plant to produce 400 000 tonnes of lithium concentrate per annum.

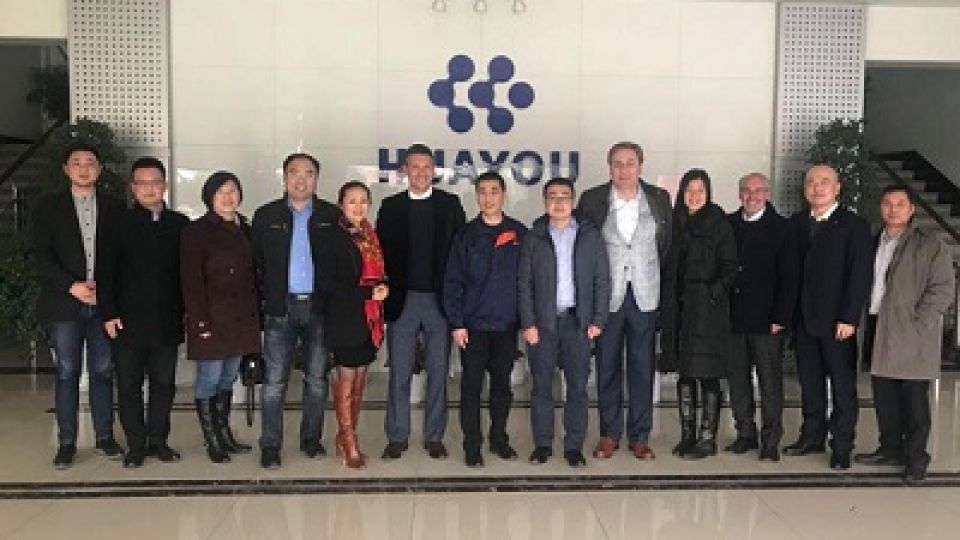

Huayou deployed executives at Arcadia Mine last month, as the firm prepares the groundwork for full-scale exploitation at one of the world’s biggest lithium endowments.

“We intend to develop the project rapidly over the next year and invest US$300 million to develop the mine and construct a process plant with a capacity to treat around 4,5 million tonnes of ore and produce 400 000 tonnes of lithium concentrate per annum,” Huayou said.

The firm has paid the US$378 million to take majority control of the operation, which is taking shape at Goromonzi, about 60km east of Harare.

Funds were transferred to Prospect Lithium Zimbabwe in March, according to corporate data.

The firm has deployed a team led by general manager, Haijun Zhu to take charge of the operation.