STEEL producer Dinson Iron and Steel Company (Disco) is set to begin commercial production later this year or early 2025, aiming to produce 600 000 tonnes of steel annually and generate US$1 billion in revenue. Disco is one of four subsidiaries under Zhejiang Dinson Holding Co. Ltd, which is part of the Chinese-based steel and nickel giant, Tsingshan Holding Group. In light of these ambitious goals, our group deputy business editor, Tatira Zwinoira (TZ), sat down with Dinson projects director Wilfred Motsi (WM) to discuss the company’s targets and strategies. Below are excerpts from their recent interview at Disco’s steel-making plant, currently under construction in Manhize:

TZ: How long have you been here?

WM: We have been here since 2001. Actually, we started construction at the end of 2001. But, the actual construction was in 2002. Our first production of pig iron started this year, June. We started producing pig iron. But, in actual fact, we are not at full capacity with the pig iron. We are still doing a little bit of test runs. We are producing about 1 400 tonnes a day, which actually is about 6% of the total production of our plant. However, we have started a new line where we are producing steel billets. But it was just a test run. We have also managed to produce just a few pig bars for the steel billets.

TZ: The steel production will come from steel billets. Is that correct?

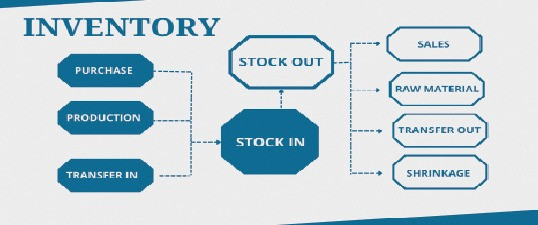

WM: What happens is for us to produce pig iron, we have certain raw materials which we actually mix. The first raw material, which is very critical, is the iron ore itself.

TZ: Is it mined in this area?

WM: It is mined here in Manhize range. And then we have limestone, which is used as a flux to attract impurities from the iron ore, which is also mined in Lalapanzi, Masvingo, and part of Mberengwa. And then the other critical mineral which we also feed into the blast furnace is cooking coke. Coke is a very important ingredient in terms of generating energy. The coke is coming from one of our subsidiaries, Dinson Colliery. When the three components mix, they form what is called a sintering cake.

TZ: So, the three components, just as a refresher, are iron ore, coke, and limestone?

- Chinese man gets 20 years in Rwanda for whipping a local man

- In Conversation with Trevor: ICT guru Stafford Masie speaks out

- In Conversation with Trevor: ICT guru Stafford Masie speaks out

- Africa’s ‘largest’ ferrochrome plant takes shape

Keep Reading

WM: Yes. Those are the three major raw materials. So those three, when they mix, form what is called a sinter cake. This is the sinter cake now, which is then fed into the blast furnace, where now it is molten, and we produce what is called pig iron. Pig iron can be used by other foundries to make things, which actually need iron.

But basically, it is a raw material for the production of steel itself. It is further refined. For the carbon steel, we have got low carbon steel, we have got high carbon steel, or we have got mild steel. Basically, these are some of the products, which come from steel and those steel billets now will be having different lengths. In other words, they are further now processed to produce the steel products.

TZ: So, this thing produces steel billets, and the steel billets are further processed to make different types of steel?

WM: Yes. In other words, that is where you can produce a rebar, which are used for construction. The angle ions are used for steelworks, and even the iron sheets which are also used for roofing houses. We can even use those (steel billets) to produce what are called columns.

And then we have what are called flat bars. These flat bars can also be used to make different shapes. And then even the steel billets can be all further processed to produce wire itself. That, or maybe, round bars also, can then be also produced to produce bolts, nuts and any other products from steel.

TZ: Can it also be used to make the body of a vehicle and stuff like that?

WM: As I have said, this type of steel making, actually, is the backbone for any industry, especially heavy industry. If it is the backbone of heavy industry, machines which you use for agriculture are also made from steel. The automobile industry also benefits from steel. So, almost 90% of the car automobile components actually are made from steel.

TZ: What other uses besides construction, vehicle manufacturing, can steel be used for?

WM: Steel, as I have said, is the backbone for any industry in Zimbabwe. It can be used for various uses.

It can be used for construction, for producing heavy machinery, which is used for mining. It is used also to produce furniture. There is also steel; utilities which we use in our houses. They are also made from steel.

TZ: When you manufacture this steel, what is it going to be used for?

WM: As a company, we are saying we produce the steel billets, which can be further processed by other partners who can come in. So, from us, they can buy the pig iron which they can also use to produce pig steel billets for themselves, or they can buy the steel billets which they can use now to make rebars, bolts, wire etc.

TZ: You said you are already making some revenue.

WM: To be honest with you, we have not started any exportation.

Because, actually, in whatever we are doing, we are producing below capacity. But, in future, that is when we start realising revenue.

The pig iron, which we are producing right now, is the raw material, which we are going to use for the steel billets. These are the steel billets which are going to be exported in the near future.

TZ: Let us talk about when it is all said and done. How many tonnes will you be able to manufacture per annum from this factory?

WM: In terms of tonnage per year, from the first phase of the steel plant, we are looking at 600 000 metric tonnes of carbon steel, like steel billets as we were saying. Then, for revenue, it depends on whether we are selling that steel as billets or finished products. But we are just focusing on US$3 billion to start with.

TZ: Is this from just the first phase?

WM: Yes.

TZ: When will you be operational?

WM: If everything goes according to plan, we are looking at the end of this year to the beginning of next year.

That is when we will start the full production at the plant.

TZ: And then you will be able to produce 600 000 tonnes per annum after, with a target of US$3 billion revenue?

WM: Yes. But, let’s put it at maybe US$1 billion because we have to recover some costs at the same time.

TZ: Speaking of costs, how much did the holding company invest into the factory and how much more is needed?

WM: Right, already, as a company, we are saying we have actually pledged through the government of Zimbabwe that we are going to invest about US$2 billion. Not for this project only, but all the projects which we are going to do in Zimbabwe with the other subsidiaries.

TZ: How about this one?

WM: Actually, to complete the whole, I think we talked about US$1,5 billion. So, in other words, for what we have sunk so far, this is the figure which I was talking about of US$1 billion, which has been sunk.

Those figures are just from my estimations. The actual costing will be done.

TZ: For capex next year, what are you looking at?

WM: About US$500 000.

TZ: Are you facing any challenges as a company so far?

WM: No. So far, so good in terms of challenges! But of course this year there was drought.

So we are also expecting that there will be some little bit of shortage of water. We have already talked to other partners, Zinwa (Zimbabwe National Water Authority), where we are going to construct one of the biggest dams around the area.