There are so many things that new farm owners in Zimbabwe take for granted that are in fact integral to the farming business.One such thing is refrigeration which is a key component to successful farming.

To begin with, every farm needs a small refrigerator to keep its chemicals, especially for animals, under cool conditions.

Cold rooms

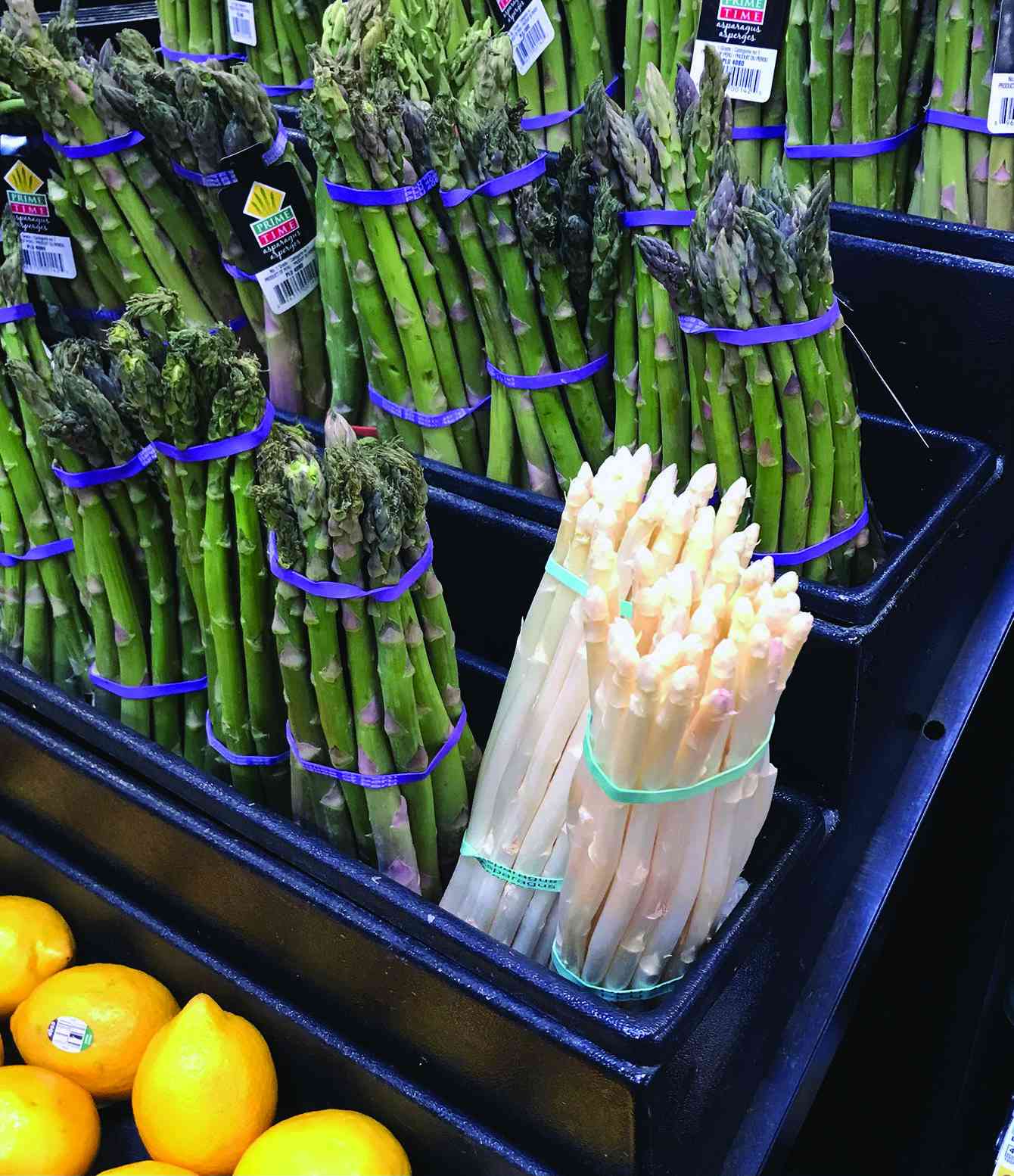

Fresh produce like peas, fine beans, peppers and many other vegetables require low temperatures as soon as they are harvested to maintain quality. This means that farmers need to invest in cold rooms at their farms if they are to meet good standards for other produce. Agricultural producers use a variety of refrigeration systems to extend the shelf life of perishable materials. Cooling not only reduces the potential for spoiling due to bacterial growth but also reduces humidity levels for some products. Refrigeration may also be used during sorting, processing, packaging, and storage.

Fruit and vegetable farmers must cool many of their products quickly after harvest; removal of field heat is important to maintaining produce quality and shelf life.

Fruit and vegetable farm refrigeration systems are operated most intensively during the warmest months of the year, often when electrical costs are at their highest levels. Improving energy efficiency of refrigeration systems can therefore lead to significant savings

Milk production

Dairy farmers also rely heavily on refrigeration equipment, but on a daily rather than seasonal basis. Dairy farming is one of the most energy-intensive agricultural operations, using electrical power to operate vacuum pumps and to pump water, ventilate structures (heat and cool), provide lighting, heat water and, most importantly, refrigerate milk.

- Dairibord aims to boost exports

- Govt inputs sellers warned

- Refrigeration key in farming

- Zim’s poultry sector registers 6,2% growth

Keep Reading

Refrigeration systems with scroll compressors are 15% to 20% more efficient than traditional reciprocating compressor systems. These compressors can be used for cooling milk or for space conditioning, such as a walk-in cooler. In addition to high-technology refrigeration equipment, a variety of supplemental refrigeration technologies are available to reduce energy costs. Well water-cooled plate heat exchangers can be used to precool the milk before it enters the bulk tank.

Heat-recovery units can scavenge the discharged heat from refrigeration equipment to supplement water-heating needs while increasing the efficiency of the refrigeration system slightly. A refrigeration heat recovery (RHR) unit consists of a water storage tank and a heat exchanger. The heat exchanger can be separate from the water tank or jacketed to the outside of the storage tank and covered with insulation and a protective shell.

Jacketed storage tanks are commonly available in 50-, 80-, and 120-litre size tanks. The refrigerant inside the jacket is cooled while the water in the tank is heated. Depending on ambient conditions, the incoming refrigerant gas to the RHR heat exchanger can reach more than 200°F and then — before exiting the tank — drop to 115° to 125°F as the heat transfers to the water. Innovative systems and equipment can help agricultural producers increase energy efficiency and reduce energy costs. Energy-efficient refrigeration equipment and technologies can lower energy expenses and improve productivity. Maximum profitability from refrigerated agricultural products is only possible if the equipment is reliable and operating efficiently.

Poultry

In poultry production refrigerators are very important. If a farmer is rearing, slaughtering and selling chickens, ducks, pigs, or even fish then they definitely require refrigeration at their premises.

Gwabanayi is a practising journalist and a farmer in his own right. — 0772 865 703 or [email protected]